Introducation

Shou Chi Industrial is a professional manufacturer for FWD constant velocity products. Our product categories cover most brands of car makers’ CV Axle and related products globally. Shou Chi has sold auto parts under GCK logo and well-received in all markets over 40 years.

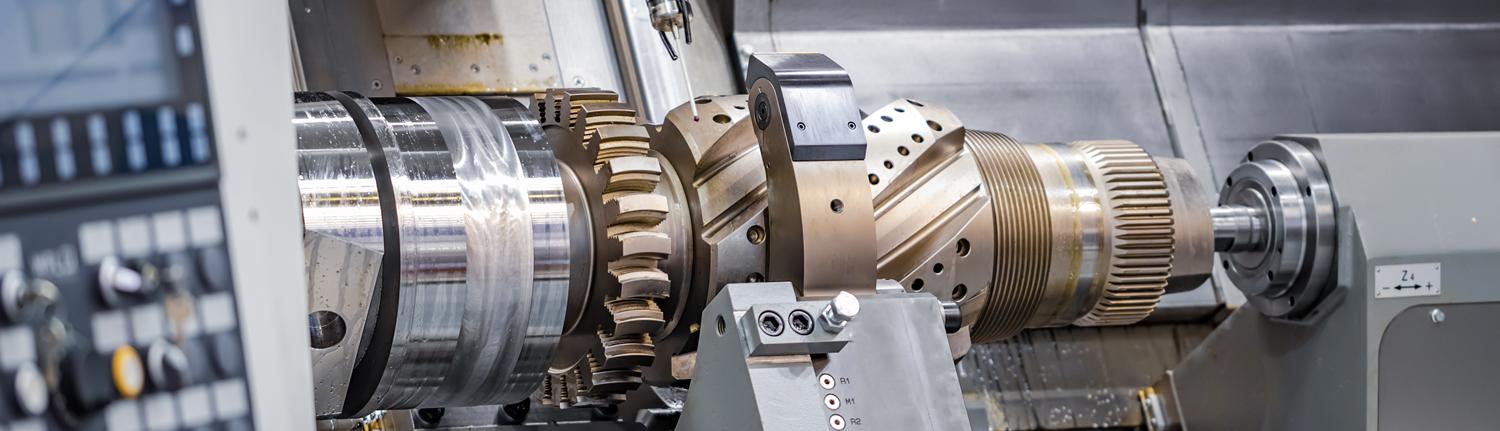

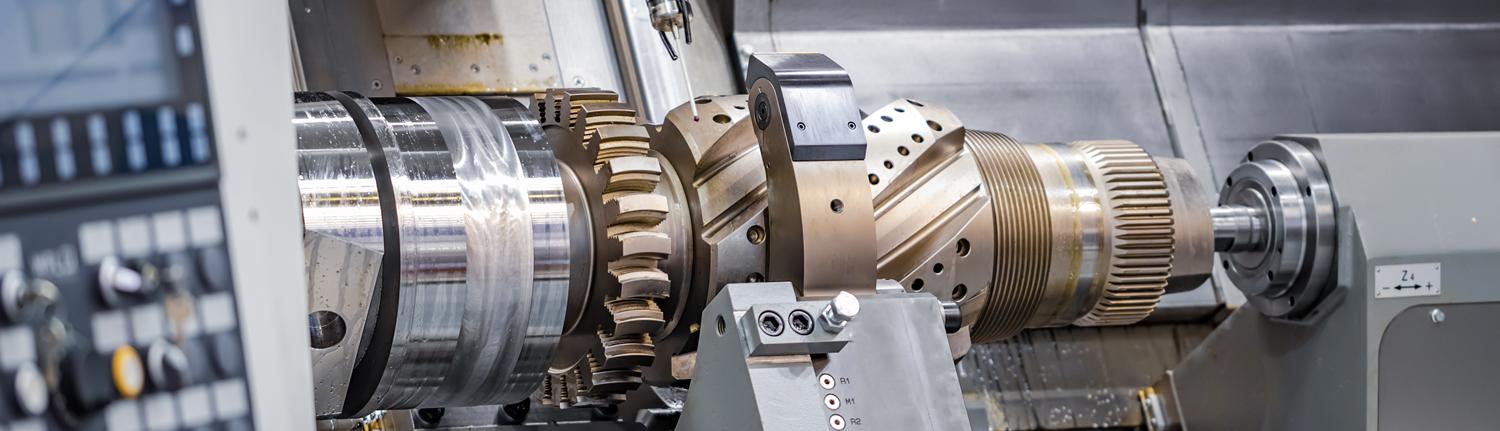

Our services cover Axle, Half-shaft, Outer joint, Inner joint, Clamps, Tripod, Center shaft, Cage, Race, ABS ring, CV Boot, Screw Nut, Grease, Chrome ball, and other related process, QC gauges, tooling and audit services.GCK’s manufacturing facilities are certificated by German TUV Sud ISO-9001 and IATF-16949. We produce reliable products.GCK products were approved and certificated to supply car markers since 1993. With years of experiences in half-shaft development and mass production, we are a trustworthy partner to many OE car makers in Taiwan, North America and China.

With reasonable design optimization, avoiding hazardous material, our products achieved new standard of Weight-Reduction and Eco-Friendly.

GCK has State-of-the-art production facility and sophisticated QC equipment, we continue to exchange data with advance National Level testing lab for auto parts related verifications and production information.GCK products cover more than 4,000 applications and always hold hundreds of thousands inventory to supply and service our customers from our Asian-Pacific Facility in Taiwan. We serve customers from global wide areas with Hard-to-find Items and rapid respond services. We continue to expand our service areas and products offered.GCK has invested in high tech equipment and assets over 300 million US dollars.

History

- 1975-Oct-01Company first established to produce Cylindrical Grinding & Horning Machines.

- 1980Devoted to manufacture motorcycle's parts; Connecting rods and others.

- 1982-1984Developed to make front-wheel half-shaft for automobile.

- 1985Add hot forging equipment to strength facility.

- 1986-1989Expansion in plant to accommodate a new computerized & Automated equipment.

- 1990100% acquisition of WEI CHOU Co., rename as SHOU CHI-We

- 1991A new plant, Wu-Jin Plant in operation for Half-Shaft

- 1992Purchase a new facility of warm & cold forging equipment including 1200 tons/2 sets, 750 tons/2 sets, and 650 tons/1 set. Modify G100 transmission shaft to meet OEM testing standard in Tien Chin Motor Company, China.

- 1994An US$1.6 million investment to made high-performance testing equipment with breaking, fatigue, and simulator to strengthen our quality control.

- 1995Wu Feng Factory was programmed to be an automated forging plant with a total of 10 production lines. SHOU CHI obtained ISO-9002 Certificate on October, 1995

- 1996SHOU CHI expanded the second site of Wu-Feng plant, and build up four high frequency induction heat treatment production line.

- 1997Produced KIA Completed half shaft and expand market to Iran OE manufacturer. Produced SUZUKI Complete half shaft and expand market to United State OE manufacturer.

- 1998QS9000 was granted by SHOU CHI Company. Added 1600 tons forging equipment and formed new production line.CV Axle Laboratory was formed for series analyze and research from raw material to all company production.

- 1999GCK started the development of our New Chinese Operation and search for New Facility Site

- 2000GCK begin the construction of New Warehouse and Office in Gardena, CA.

- 2001GCK begin the construction of New Facility in China Wu-Feng Plant new additional Facility construction completed and start operation.

- 2002China Gonghe Plant One construction completed, and area covers 200,000 square meters.

History

1975-Oct-01Company first established to produce Cylindrical Grinding & Horning Machines.1980Devoted to manufacture motorcycle's parts; Connecting rods and others.1982-1984Developed to make front-wheel half-shaft for automobile.1985Add hot forging equipment to strength facility.1986-1989Expansion in plant to accommodate a new computerized & Automated equipment.1990100% acquisition of WEI CHOU Co., rename as SHOU CHI-We1991A new plant, Wu-Jin Plant in operation for Half-Shaft 1992Purchase a new facility of warm & cold forging equipment including 1200 tons/2 sets, 750 tons/2 sets, and 650 tons/1 set.Modify G100 transmission shaft to meet OEM testing standard in Tien Chin Motor Company, China.1994An US$1.6 million investment to made high-performance testing equipment with breaking, fatigue, and simulator to strengthen our quality control.1995Wu Feng Factory was programmed to be an automated forging plant with a total of 10 production lines.SHOU CHI obtained ISO-9002 Certificate on October, 19951996SHOU CHI expanded the second site of Wu-Feng plant, and build up four high frequency induction heat treatment production line.1997Produced KIA Completed half shaft and expand market to Iran OE manufacturer.Produced SUZUKI Complete half shaft and expand market to United State OE manufacturer.

1998QS9000 was granted by SHOU CHI Company.Added 1600 tons forging equipment and formed new production line.

CV Axle Laboratory was formed for series analyze and research from raw material to all company production.1999GCK started the development of our New Chinese Operation and search for New Facility Site2000GCK begin the construction of New Warehouse and Office in Gardena, CA.2001GCK begin the construction of New Facility in ChinaWu-Feng Plant new additional Facility construction completed and start operation.

2002China Gonghe Plant One construction completed, and area covers 200,000 square meters.